Prince Rupert's drop is a glass artifact that exhibits two properties that are the exact opposite of each other—they are extremely tough and extremely fragile at the same time.

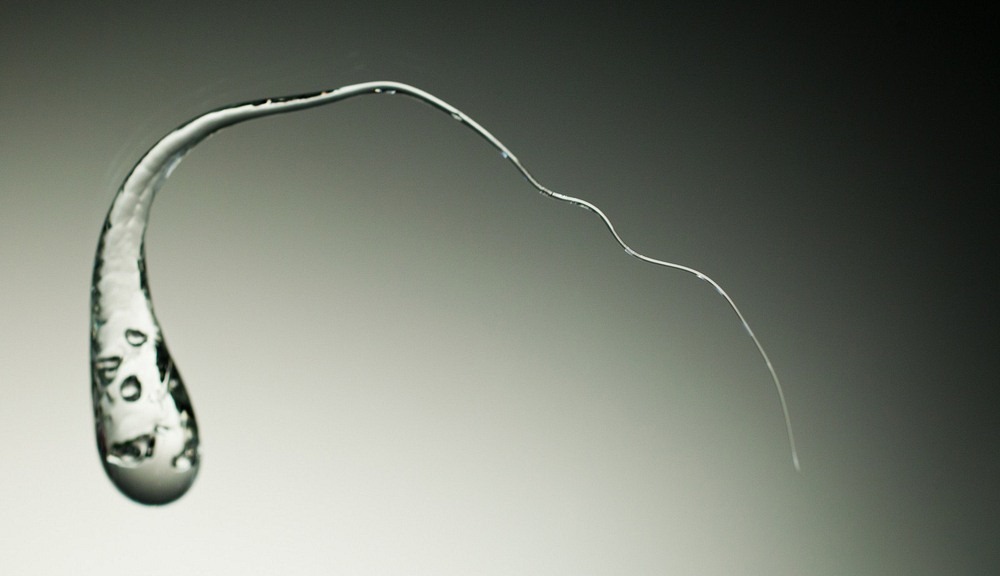

The drop looks like a tadpole with a bulbous head and a long, thin tail. The head is so strong that it can withstand the impact of a hammer, and bullets fired at it at point-blank range have been shown to shatter on impact—the bullet, not the glass. Yet, if you take the drop’s tail and snap it with your finger, it causes the entire droplet, including the hardened glass head, to explosively disintegrate into powder.

Prince Rupert's drops are made by dropping a dollop of molten glass into cold water causing its outer surface to solidify instantly, while the interior of the glass drop still remains molten. The cooled outer layer tries to contract while the molten inner layer tries to expand. As the whole thing crystallizes these opposite forces acting on the head of the drop causes it to acquire unusually high strength, yet remain fragile should something disturb the equilibrium. It’s like a stone arch—the entire thing is under extreme tension and it’s the tension that keeps the arch supported. But once you remove the keystone the whole arch comes crumbling down.

Prince Rupert's drops have been known in Germany since the 1640s. They were originally created by glassmakers in Mecklenburg in North Germany, and sold as toys and curiosities throughout Europe where they have been called by various names like ‘Prussian tears’ and ‘Dutch tears’. The glassmakers closely guarded their secret leading to a whole range of theories of how they were being produced.

The amateur English scientist Margaret Cavendish, the Duchess of Newcastle, after weeks experimenting with dozens of specimens in her lab, arrived at the conclusion that there was a tiny quantity of volatile material injected into the head which reacted violently on contact with air.

In 1660, Prince Rupert, the Duke of Cumberland and one of the founding members of the Royal Society, brought some of these drops for demonstration before the Society and King Charles II, lending his name to the glass bubbles.

Robert Hooke, who was in charge of those experiments performed before the Society, made an important early breakthrough by suggesting that it was the differential cooling of the glass after it was plunged into water that caused it to acquire this strange property, although a fuller understanding of the mechanics would elude scientists for the next three centuries.

It wasn’t until 1994, when scientists at Purdue University and the University of Cambridge using high-speed framing photography to observe the drop-shattering process concluded that the surface of each drop experiences highly compressive stresses, while the interior experiences high tension forces— a state of unequal equilibrium which can easily be disturbed by breaking the tail. Experiments shows that the bulbous head can withstand compressive forces of up to 100,000 pound per square inch. From high speed footage, it was calculated that disintegrating cracks propagated through the tail and into the head at an astounding speed of over 6,500 kilometers per hour.

Further collaborating with Tallinn University of Technology in Estonia in 2017, researchers found that in order to break a droplet, it's necessary to create a crack that can penetrate the interior tension zone in the drop. The outer compressive layer is very thin, only about 10 percent of the diameter of the head of the drop, but has a high fracture strength. Since cracks on the surface tend to grow parallel to the surface, they cannot enter the tension zone. But if the tail is cracked it causes the cracks to shoot parallel to the axis of the drop and into the tension zone releasing all the pent-up energy and causes the whole thing to shatter.

Tempered glass, commonly used in cars and mobile phones, are made using the same principle. The glass is rapidly cooled while still molten with jets of cold air creating an internal tension that keeps the surface compressed at all times. The compression prevents cracks from growing, but when the glass finally breaks it shatters into a thousand pieces. This is why car windshields shatter into tiny pieces on impact, but windshields have a special layer of adhesives that prevent the particles from flying into the car’s interior and injuring the occupants.

"The tensile stress is what usually causes materials to fracture analogous to tearing a sheet of paper in half," says Purdue postdoctoral associate Koushik Viswanathan. "But if you could change the tensile stress to a compressive stress, then it becomes difficult for cracks to grow, and this is what happens in the head portion of the Prince Rupert's drops."